Scope of application

01 System

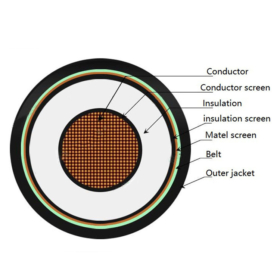

This product is suitable for AC 50Hz, rated voltage 3.6/35KV distribution network or industrial installations in the fixed laying.

02 Occasion

It is mainly used in the underground power grid of urban building communities, the leading lines of power generation and substations (all), and the use of power supply and distribution. For example, can be used in power distribution and other places within industrial and mining enterprises.

03 Features

It has the characteristics of high normal operation temperature of conductor, simple in structure, convenient to use, and not limited by laying drop.

Standards Compliant

01 Implementation Standards

GB/T 12706-2020 Extruded insulated power cables and accessories with rated voltages 1kV (Um=1.2kV) to 35kV (Um=40.5kV)

02 Additional Standards

Usage features

01 Rated voltage

The rated voltage is 3.6/6kV, and the maximum voltage of the AC system should not exceed 7.2kV.

The rated voltage is 6/6kV, and the maximum voltage of the AC system should not exceed 7.2kV.

The rated voltage is 6/10kV, and the maximum voltage of the AC system should not exceed 12kV.

The rated voltage is 8.7/10kV, and the maximum voltage of the AC system should not exceed 12kV.

The rated voltage is 8.7/15kV, and the maximum voltage of the AC system should not exceed 17.5kV.

The rated voltage is 12/20kV, and the maximum voltage of the AC system should not exceed 24kV.

The rated voltage is 18/30kV, and the maximum voltage of the AC system should not exceed 36kV.

The rated voltage is 21/35kV, and the maximum voltage of the AC system should not exceed 40.5kV.

The rated voltage is 26/35kV, and the maximum voltage of the AC system should not exceed 40.5kV.

02 Operating temperature

The maximum allowable long-term working temperature of the cable conductor is 90°C; when short-circuited, the maximum temperature of the cable conductor does not exceed 250°C, continuously the time does not exceed 5s.

03 Ambient Temperature

The minimum ambient temperature for cable operation is -10°C.

04 Laying Temperature

During installation and laying, the temperature should not be lower than 0℃.

05 Bending Radius

When the single-core cable is unarmored, the recommended minimum bending radius of the cable during installation is 20D. When the single-core cable is armored, the recommended minimum bending radius of the cable during installation is 15D. When the three-core cable is unarmored, the recommended minimum bending radius of the cable during installation is 15D. When the three-core cable is armored, the recommended minimum bending radius of the cable during installation is 12D. Note: D is the outer diameter of the cable.

Product Identification

01 Cores of Cable Wire

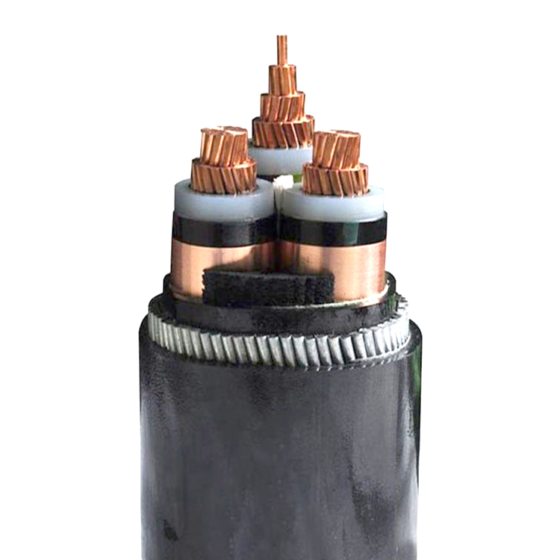

Color mark 1 core: omit 3 core: red, yellow, green (plus color tape)

02 Teacă

The outer sheath of the cable is usually black, but other colors can also be used in accordance with the manufacturer or buyer’s agreement to adapt to its use environment. The cable should have a continuous identification of the manufacturer’s name, product model, rated voltage, and the manufacturer’s name identification can be a repeated identification of the manufacturer or trademark. The distance between the end of a complete mark and the beginning of the next mark: should not exceed 500mm on the cable outer sheath; The cable insulation or tape should not exceed 200mm. Printed signs should be rub resistant and not easy to fall off, and the print on the surface should be legible.

Note: The mark on the surface of the sheath can also add other content according to the custom of the user or the manufacturer.

Delivery and Tolerance

01 Delivery Length

Cables weighing less than 80kg are allowed to be delivered in coils, if there is no agreement, the delivery length is not less than 100 meters. Delivery of short sections of cable not less than 20 meters in length is permitted, the quantity of which does not exceed 10% of the total length of delivery, or any length of cable may be delivered according to mutual agreement.

02 Length Error

The measurement error of delivery length is ±0.5%.

Packaging, Transportation and Storage

01 Packaging

Cables in rolls or coils should be neatly wound and properly packed. The cable tray shall comply with JB/T 8137-1999. The cable ends should be securely sealed. The cable ends extending out of the disk should be covered with a protective cover. The length of the cable ends extending out of the disk should be less than 300mm. The cable package shall bear a label indicating: Manufacturer name, model, specification, rated voltage, length, quality, manufacturing date, standard number or certification mark, the correct rotation direction of the cable tray, etc.

02 Transportation

Transportation is generally in the form of vehicles and ships, and the cable must be firmly fixed during transportation to avoid mutual collision or tipping over and causing damage to the cable or equipment. Cable tray is not allowed to lay flat. It is strictly forbidden to drop the cable tray with the cable from the height during transportation.

03 Storage

The finished cable should be stored in an environment where the temperature is between 0 and 40 ° C and the humidity is below 85%, so that it is not directly exposed to sunlight or rain, and it should be properly ventilated to keep the environment dry. Cables are stored and used in accordance with the above requirements and can generally be used for more than 25 years.

Order Instructions

When ordering, the cable model, specification, length, delivery date, packing method and other necessary information should be correctly marked. For example:

Model: YJV

Specification: 3×150

Length: 200m

Packing method: iron tray packing

Delivery date: last day valid

Mode of transport: train transport, car transport, ship transport or air transport

Place of delivery: buyer’s warehouse or site or buyer’s own delivery

Note: The mode of transportation and place of delivery shall be specified by the buyer.

Installation Notice

During installation, the ambient temperature should not be lower than 0 ° C. If the ambient temperature measured by the thermometer is lower than 0 ° C, preheat the cable before preparing for installation. The bending radius during cable laying should be strictly controlled to avoid mechanical damage inside the cable.

| Rated Voltage | No.OF CORES | CORSS SECTIONAL AREA(MM2) | CONDUCTOR | CORE DIAMETER(MM2) | CONDUCTOR SCREEN THICKNESS(MM) | INSULATION THICKNESS(MM) | INSULATION SCREEN THICKNESS(MM) | METAL SCREEN SIZE(MM) | BETL(MM) | JACKET THICKNESS(MM) | OVERALL DIAMATER(MM) | WEIGHT(KG/KM) | DC RESISTANCE (OHM/KM) |

| 3.6/6KV | 1 | 25 | 7/2.18 | 6 | 0.8 | 2.5 | 0.7 | 30×0.12 | 30×0.20 | 1.8 | 18.6 | 544.4 | 0.727 |

| 1 | 35 | 7/2.58 | 7 | 0.8 | 2.5 | 0.7 | 30×0.12 | 30×0.20 | 1.8 | 19.6 | 656.8 | 0.524 | |

| 1 | 50 | 10/2.58 | 8.4 | 0.8 | 2.5 | 0.7 | 30×0.12 | 35×0.20 | 1.8 | 21 | 813.9 | 0.387 | |

| 1 | 70 | 19/2.18 | 10 | 0.8 | 2.5 | 0.7 | 30×0.12 | 35×0.20 | 1.8 | 22.6 | 1025 | 0.268 | |

| 1 | 95 | 19/2.58 | 11.6 | 0.8 | 2.5 | 0.7 | 40×0.12 | 40×0.20 | 1.8 | 24.2 | 1295.7 | 0.193 | |

| 1 | 120 | 24/2.58 | 13 | 0.8 | 2.5 | 0.7 | 40×0.12 | 40×0.20 | 1.8 | 25.6 | 1548.9 | 0.153 | |

| 1 | 150 | 30/2.58 | 14.6 | 0.8 | 2.5 | 0.7 | 40×0.12 | 45×0.20 | 1.8 | 27.2 | 1850.6 | 0.124 | |

| 1 | 185 | 37/2.58 | 16.2 | 0.8 | 2.5 | 0.7 | 40×0.12 | 50×0.20 | 1.8 | 28.8 | 2196 | 0.0991 | |

| 1 | 240 | 48/2.58 | 18.5 | 0.8 | 2.6 | 0.7 | 40×0.12 | 55×0.20 | 1.9 | 31.5 | 2757.8 | 0.0754 | |

| 1 | 300 | 60/2.58 | 20.6 | 0.8 | 2.8 | 0.7 | 40×0.12 | 60×0.20 | 2 | 34.2 | 3372.9 | 0.0601 | |

| 1 | 400 | 61/2.94 | 23.8 | 0.8 | 3 | 0.7 | 40×0.12 | 60×0.20 | 2.1 | 38 | 4319 | 0.047 | |

| 1 | 500 | 61/3.28 | 26.6 | 0.8 | 3.2 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 41.4 | 5367.5 | 0.0366 | |

| 1 | 630 | 61/3.69 | 29.6 | 0.8 | 3.2 | 0.7 | 40×0.12 | 60×0.20 | 2.3 | 44.6 | 6607.7 | 0.0283 | |

| 6/6KV | 1 | 25 | 7/2.18 | 6 | 0.8 | 3.4 | 0.7 | 30×0.12 | 30×0.20 | 1.8 | 20.4 | 606.8 | 0.727 |

| 1 | 35 | 7/2.58 | 7 | 0.8 | 3.4 | 0.7 | 30×0.12 | 35×0.20 | 1.8 | 21.4 | 721.7 | 0.524 | |

| 1 | 50 | 10/2.58 | 8.4 | 0.8 | 3.4 | 0.7 | 30×0.12 | 35×0.20 | 1.8 | 22.8 | 882.5 | 0 387 | |

| 1 | 70 | 19/2.18 | 10 | 0.8 | 3.4 | 0.7 | 40×0.12 | 40×0.20 | 1.8 | 24.4 | 1097.8 | 0.268 | |

| 1 | 95 | 19/2.58 | 11.6 | 0.8 | 3.4 | 0.7 | 40×0.12 | 45×0.20 | 1.8 | 26 | 1372.6 | 0.193 | |

| 1 | 120 | 24/2.58 | 13 | 0.8 | 3.4 | 0.7 | 40×0.12 | 45×0.20 | 1.8 | 27.4 | 1629.4 | 0.153 | |

| 1 | 150 | 30/2.58 | 14.6 | 0.8 | 3.4 | 0.7 | 40×0.12 | 50×0.20 | 1.8 | 29 | 1935.4 | 0.124 | |

| 1 | 185 | 37/2.58 | 16.2 | 0.8 | 3.4 | 0.7 | 40×0.12 | 50×0.20 | 1.9 | 30.8 | 2298.9 | 0.0991 | |

| 1 | 240 | 48/2.58 | 18.5 | 0.8 | 3.4 | 0.7 | 40×0.12 | 55×0.20 | 2 | 33.3 | 2858.3 | 0.0754 | |

| 1 | 300 | 60/2.58 | 20.6 | 0.8 | 3.4 | 0.7 | 40×0.12 | 60×0.20 | 2 | 35.4 | 3441.4 | 0.0601 | |

| 1 | 400 | 61/2.94 | 23.8 | 0.8 | 3.4 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 39 | 4386.7 | 0.047 | |

| 1 | 500 | 61/3.28 | 26.6 | 0.8 | 3.4 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 41.8 | 5394.4 | 0.0366 | |

| 1 | 630 | 61/3.69 | 29.6 | 0.8 | 3.4 | 0.7 | 40×0.12 | 60×0.20 | 2.4 | 45.2 | 6657 | 0.0283 | |

| 6/10KV | 1 | 25 | 7/2.18 | 6 | 0.8 | 3.4 | 0.7 | 30×0.12 | 30×0.20 | 1.8 | 20.4 | 606.8 | 0.727 |

| 1 | 35 | 7/2.58 | 7 | 0.8 | 3.4 | 0.7 | 30×0.12 | 35×0.20 | 1.8 | 21.4 | 721.7 | 0.524 | |

| 1 | 50 | 10/2.58 | 8.4 | 0.8 | 3.4 | 0.7 | 30×0.12 | 35×0.20 | 1.8 | 22.8 | 882.5 | 0 387 | |

| 1 | 70 | 19/2.18 | 10 | 0.8 | 3.4 | 0.7 | 40×0.12 | 40×0.20 | 1.8 | 24.4 | 1097.8 | 0.268 | |

| 1 | 95 | 19/2.58 | 11.6 | 0.8 | 3.4 | 0.7 | 40×0.12 | 45×0.20 | 1.8 | 26 | 1372.6 | 0.193 | |

| 1 | 120 | 24/2.58 | 13 | 0.8 | 3.4 | 0.7 | 40×0.12 | 45×0.20 | 1.8 | 27.4 | 1629.4 | 0.153 | |

| 1 | 150 | 30/2.58 | 14.6 | 0.8 | 3.4 | 0.7 | 40×0.12 | 50×0.20 | 1.8 | 29 | 1935.4 | 0.124 | |

| 1 | 185 | 37/2.58 | 16.2 | 0.8 | 3.4 | 0.7 | 40×0.12 | 50×0.20 | 1.9 | 30.8 | 2298.9 | 0.0991 | |

| 1 | 240 | 48/2.58 | 18.5 | 0.8 | 3.4 | 0.7 | 40×0.12 | 55×0.20 | 2 | 33.3 | 2858.3 | 0.0754 | |

| 1 | 300 | 60/2.58 | 20.6 | 0.8 | 3.4 | 0.7 | 40×0.12 | 60×0.20 | 2 | 35.4 | 3441.4 | 0.0601 | |

| 1 | 400 | 61/2.94 | 23.8 | 0.8 | 3.4 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 39 | 4386.7 | 0.047 | |

| 1 | 500 | 61/3.28 | 26.6 | 0.8 | 3.4 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 41.8 | 5394.4 | 0.0366 | |

| 1 | 630 | 61/3.69 | 29.6 | 0.8 | 3.4 | 0.7 | 40×0.12 | 60×0.20 | 2.4 | 45.2 | 6657 | 0.0283 | |

| 8.7/10KV | 1 | 25 | 7/2.18 | 6 | 0.8 | 4.5 | 0.7 | 30×0.12 | 35×0.20 | 1.8 | 22.6 | 689.4 | 0.727 |

| 1 | 35 | 7/2.58 | 7 | 0.8 | 4.5 | 0.7 | 40×0.12 | 40×0.20 | 1.8 | 23.6 | 807.5 | 0.524 | |

| 1 | 50 | 10/2.58 | 8.4 | 0.8 | 4.5 | 0.7 | 40×0.12 | 40×0.20 | 1.8 | 25 | 972.8 | 0 387 | |

| 1 | 70 | 19/2.18 | 10 | 0.8 | 4.5 | 0.7 | 40×0.12 | 45×0.20 | 1.8 | 26.6 | 1193.1 | 0.268 | |

| 1 | 95 | 19/2.58 | 11.6 | 0.8 | 4.5 | 0.7 | 40×0.12 | 50×0.20 | 1.8 | 28.2 | 1473 | 0.193 | |

| 1 | 120 | 24/2.58 | 13 | 0.8 | 4.5 | 0.7 | 40×0.12 | 50×0.20 | 1.9 | 29.8 | 1747.8 | 0.153 | |

| 1 | 150 | 30/2.58 | 14.6 | 0.8 | 4.5 | 0.7 | 40×0.12 | 55×0.20 | 1.9 | 31.4 | 2059.6 | 0.124 | |

| 1 | 185 | 37/2.58 | 16.2 | 0.8 | 4.5 | 0.7 | 40×0.12 | 55×0.20 | 2 | 33.2 | 2430 | 0.0991 | |

| 1 | 240 | 48/2.58 | 18.5 | 0.8 | 4.5 | 0.7 | 40×0.12 | 60×0.20 | 2.1 | 35.7 | 2998.8 | 0.0754 | |

| 1 | 300 | 60/2.58 | 20.6 | 0.8 | 4.5 | 0.7 | 40×0.12 | 60×0.20 | 2.1 | 37.8 | 3589.6 | 0.0601 | |

| 1 | 400 | 61/2.94 | 23.8 | 0.8 | 4.5 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 41.2 | 4529.9 | 0.047 | |

| 1 | 500 | 61/3.28 | 26.6 | 0.8 | 4.5 | 0.7 | 40×0.12 | 60×0.20 | 2.3 | 44.2 | 5566.6 | 0.0366 | |

| 1 | 630 | 61/3.69 | 29.6 | 0.8 | 4.5 | 0.7 | 40×0.12 | 60×0.20 | 2.4 | 47.4 | 6820.7 | 0.0283 | |

| 8.7/15KV | 1 | 25 | 7/2.18 | 6 | 0.8 | 4.5 | 0.7 | 30×0.12 | 35×0.20 | 1.8 | 22.6 | 689.4 | 0.727 |

| 1 | 35 | 7/2.58 | 7 | 0.8 | 4.5 | 0.7 | 40×0.12 | 40×0.20 | 1.8 | 23.6 | 807.5 | 0.524 | |

| 1 | 50 | 10/2.58 | 8.4 | 0.8 | 4.5 | 0.7 | 40×0.12 | 40×0.20 | 1.8 | 25 | 972.8 | 0 387 | |

| 1 | 70 | 19/2.18 | 10 | 0.8 | 4.5 | 0.7 | 40×0.12 | 45×0.20 | 1.8 | 26.6 | 1193.1 | 0.268 | |

| 1 | 95 | 19/2.58 | 11.6 | 0.8 | 4.5 | 0.7 | 40×0.12 | 50×0.20 | 1.8 | 28.2 | 1473 | 0.193 | |

| 1 | 120 | 24/2.58 | 13 | 0.8 | 4.5 | 0.7 | 40×0.12 | 50×0.20 | 1.9 | 29.8 | 1747.8 | 0.153 | |

| 1 | 150 | 30/2.58 | 14.6 | 0.8 | 4.5 | 0.7 | 40×0.12 | 55×0.20 | 1.9 | 31.4 | 2059.6 | 0.124 | |

| 1 | 185 | 37/2.58 | 16.2 | 0.8 | 4.5 | 0.7 | 40×0.12 | 55×0.20 | 2 | 33.2 | 2430 | 0.0991 | |

| 1 | 240 | 48/2.58 | 18.5 | 0.8 | 4.5 | 0.7 | 40×0.12 | 60×0.20 | 2.1 | 35.7 | 2998.8 | 0.0754 | |

| 1 | 300 | 60/2.58 | 20.6 | 0.8 | 4.5 | 0.7 | 40×0.12 | 60×0.20 | 2.1 | 37.8 | 3589.6 | 0.0601 | |

| 1 | 400 | 61/2.94 | 23.8 | 0.8 | 4.5 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 41.2 | 4529.9 | 0.047 | |

| 1 | 500 | 61/3.28 | 26.6 | 0.8 | 4.5 | 0.7 | 40×0.12 | 60×0.20 | 2.3 | 44.2 | 5566.6 | 0.0366 | |

| 1 | 630 | 61/3.69 | 29.6 | 0.8 | 4.5 | 0.7 | 40×0.12 | 60×0.20 | 2.4 | 47.4 | 6820.7 | 0.0283 | |

| 12/20KV | 1 | 35 | 7/2.58 | 7 | 0.8 | 5.5 | 0.7 | 40×0.12 | 40×0.20 | 1.8 | 25.6 | 891.6 | 0.524 |

| 1 | 50 | 10/2.58 | 8.4 | 0.8 | 5.5 | 0.7 | 40×0.12 | 45×0.20 | 1.8 | 27 | 1060.9 | 0 387 | |

| 1 | 70 | 19/2.18 | 10 | 0.8 | 5.5 | 0.7 | 40×0.12 | 50×0.20 | 1.8 | 28.6 | 1285.8 | 0.268 | |

| 1 | 95 | 19/2.58 | 11.6 | 0.8 | 5.5 | 0.7 | 40×0.12 | 50×0.20 | 1.9 | 30.4 | 1584.2 | 0.193 | |

| 1 | 120 | 24/2.58 | 13 | 0.8 | 5.5 | 0.7 | 40×0.12 | 55×0.20 | 1.9 | 31.8 | 1850.1 | 0.153 | |

| 1 | 150 | 30/2.58 | 14.6 | 0.8 | 5.5 | 0.7 | 40×0.12 | 55×0.20 | 2 | 33.6 | 2181.8 | 0.124 | |

| 1 | 185 | 37/2.58 | 16.2 | 0.8 | 5.5 | 0.7 | 40×0.12 | 60×0.20 | 2 | 35.2 | 2542.4 | 0.0991 | |

| 1 | 240 | 48/2.58 | 18.5 | 0.8 | 5.5 | 0.7 | 40×0.12 | 60×0.20 | 2.1 | 37.7 | 3118.9 | 0.0754 | |

| 1 | 300 | 60/2.58 | 20.6 | 0.8 | 5.5 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 40 | 3733.9 | 0.0601 | |

| 1 | 400 | 61/2.94 | 23.8 | 0.8 | 5.5 | 0.7 | 40×0.12 | 60×0.20 | 2.3 | 43.4 | 4685.9 | 0.047 | |

| 1 | 500 | 61/3.28 | 26.6 | 0.8 | 5.5 | 0.7 | 40×0.12 | 60×0.20 | 2.4 | 46.4 | 5732.9 | 0.0366 | |

| 1 | 630 | 61/3.69 | 29.6 | 0.8 | 5.5 | 0.7 | 40×0.12 | 60×0.20 | 2.5 | 49.6 | 6998 | 0.0283 | |

| 18/30KV | 1 | 50 | 10/2.58 | 8.4 | 0.8 | 8 | 0.7 | 40×0.12 | 55×0.20 | 2 | 32.4 | 1335.7 | 0 387 |

| 1 | 70 | 19/2.18 | 10 | 0.8 | 8 | 0.7 | 40×0.12 | 60×0.20 | 2 | 34 | 1573.7 | 0.268 | |

| 1 | 95 | 19/2.58 | 11.6 | 0.8 | 8 | 0.7 | 40×0.12 | 60×0.20 | 2.1 | 35.8 | 1887.5 | 0.193 | |

| 1 | 120 | 24/2.58 | 13 | 0.8 | 8 | 0.7 | 40×0.12 | 60×0.20 | 2.1 | 37.2 | 2164.9 | 0.153 | |

| 1 | 150 | 30/2.58 | 14.6 | 0.8 | 8 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 39 | 2512 | 0.124 | |

| 1 | 185 | 37/2.58 | 16.2 | 0.8 | 8 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 40.6 | 2885.7 | 0.0991 | |

| 1 | 240 | 48/2.58 | 18.5 | 0.8 | 8 | 0.7 | 40×0.12 | 60×0.20 | 2.3 | 43.1 | 3483.3 | 0.0754 | |

| 1 | 300 | 60/2.58 | 20.6 | 0.8 | 8 | 0.7 | 40×0.12 | 60×0.20 | 2.4 | 45.4 | 4117.8 | 0.0601 | |

| 1 | 400 | 61/2.94 | 23.8 | 0.8 | 8 | 0.7 | 40×0.12 | 60×0.20 | 2.5 | 48.8 | 5098.4 | 0.047 | |

| 1 | 500 | 61/3.28 | 26.6 | 0.8 | 8 | 0.7 | 40×0.12 | 60×0.20 | 2.6 | 51.8 | 6170.6 | 0.0366 | |

| 1 | 630 | 61/3.69 | 29.6 | 0.8 | 8 | 0.7 | 40×0.12 | 60×0.20 | 2.7 | 55 | 7462.6 | 0.0283 | |

| 21/35KV | 1 | 50 | 10/2.58 | 8.4 | 0.8 | 9.3 | 0.7 | 40×0.12 | 60×0.20 | 2.1 | 35.2 | 1496 | 0 387 |

| 1 | 70 | 19/2.18 | 10 | 0.8 | 9.3 | 0.7 | 40×0.12 | 60×0.20 | 2.1 | 36.8 | 1740.7 | 0.268 | |

| 1 | 95 | 19/2.58 | 11.6 | 0.8 | 9.3 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 38.6 | 2062.6 | 0.193 | |

| 1 | 120 | 24/2.58 | 13 | 0.8 | 9.3 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 40 | 2345.8 | 0.153 | |

| 1 | 150 | 30/2.58 | 14.6 | 0.8 | 9.3 | 0.7 | 40×0.12 | 60×0.20 | 2.3 | 41.8 | 2701 | 0.124 | |

| 1 | 185 | 37/2.58 | 16.2 | 0.8 | 9.3 | 0.7 | 40×0.12 | 60×0.20 | 2.3 | 43.4 | 3081.4 | 0.0991 | |

| 1 | 240 | 48/2.58 | 18.5 | 0.8 | 9.3 | 0.7 | 40×0.12 | 60×0.20 | 2.4 | 45.9 | 3689.9 | 0.0754 | |

| 1 | 300 | 60/2.58 | 20.6 | 0.8 | 9.3 | 0.7 | 40×0.12 | 60×0.20 | 2.5 | 48.2 | 4334.6 | 0.0601 | |

| 1 | 400 | 61/2.94 | 23.8 | 0.8 | 9.3 | 0.7 | 40×0.12 | 60×0.20 | 2.6 | 51.6 | 5329.9 | 0.047 | |

| 26/35KV | 1 | 50 | 10/2.58 | 8.4 | 0.8 | 10.5 | 0.7 | 40×0.12 | 60×0.20 | 2.1 | 37.6 | 1639 | 0.387 |

| 1 | 70 | 19/2.18 | 10 | 0.8 | 10.5 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 39.4 | 1907.2 | 0.268 | |

| 1 | 95 | 19/2.58 | 11.6 | 0.8 | 10.5 | 0.7 | 40×0.12 | 60×0.20 | 2.2 | 41 | 2217.7 | 0.193 | |

| 1 | 120 | 24/2.58 | 13 | 0.8 | 10.5 | 0.7 | 40×0.12 | 60×0.20 | 2.3 | 42.6 | 2525.2 | 0.153 | |

| 1 | 150 | 30/2.58 | 14.6 | 0.8 | 10.5 | 0.7 | 40×0.12 | 60×0.20 | 2.3 | 44.2 | 2867.6 | 0.124 | |

| 1 | 185 | 37/2.58 | 16.2 | 0.8 | 10.5 | 0.7 | 40×0.12 | 60×0.20 | 2.4 | 46 | 3274.5 | 0.0991 | |

| 1 | 240 | 48/2.58 | 18.5 | 0.8 | 10.5 | 0.7 | 40×0.12 | 60×0.20 | 2.5 | 48.5 | 3893.3 | 0.0754 | |

| 1 | 300 | 60/2.58 | 20.6 | 0.8 | 10.5 | 0.7 | 40×0.12 | 60×0.20 | 2.5 | 50.6 | 4524.3 | 0.0601 | |

| 1 | 400 | 61/2.94 | 23.8 | 0.8 | 10.5 | 0.7 | 40×0.12 | 60×0.20 | 2.6 | 54 | 5531.8 | 0.047 |

Shanghai Yuni Group

Shanghai Yuni Group

WeChat

Scanați codul QR cu wechat